I work to create enduring products that serve people.

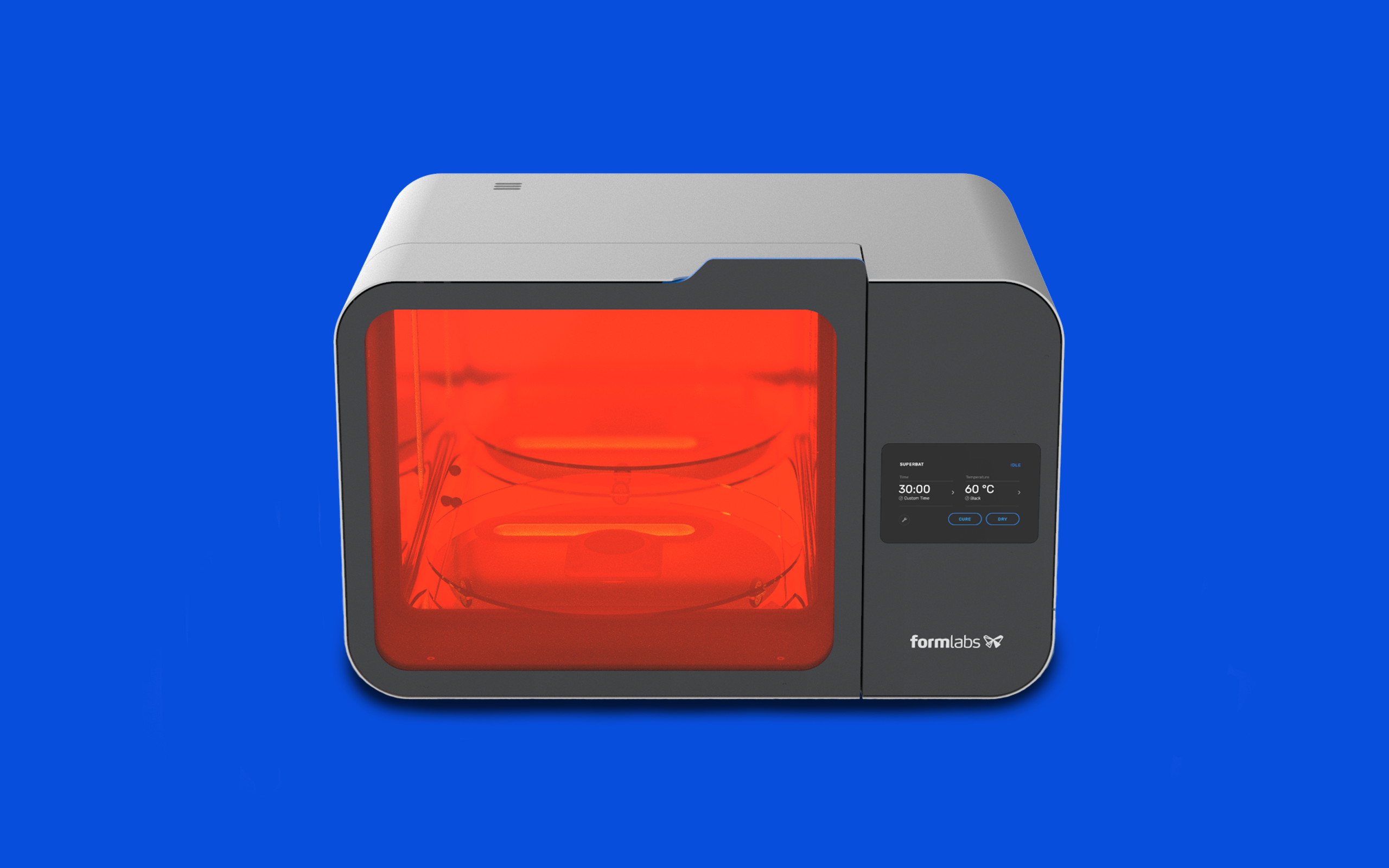

Form Cure L and Form Wash L

2020, FormlabsIndustrial-grade SLA post-processing made friendly

Work

︎ Sketching

︎ Concept development

︎ Prototyping

︎ User testing

︎ DFM

︎ CMF specification

︎ Visualization

︎ Design leadership

︎ Sketching

︎ Concept development

︎ Prototyping

︎ User testing

︎ DFM

︎ CMF specification

︎ Visualization

︎ Design leadership

Goals

︎ Good accessibility and workflow cleanliness

︎ Quick to market

︎ High impact per $/effort

︎ Product ecosystem and brand fit

︎ Good accessibility and workflow cleanliness

︎ Quick to market

︎ High impact per $/effort

︎ Product ecosystem and brand fit

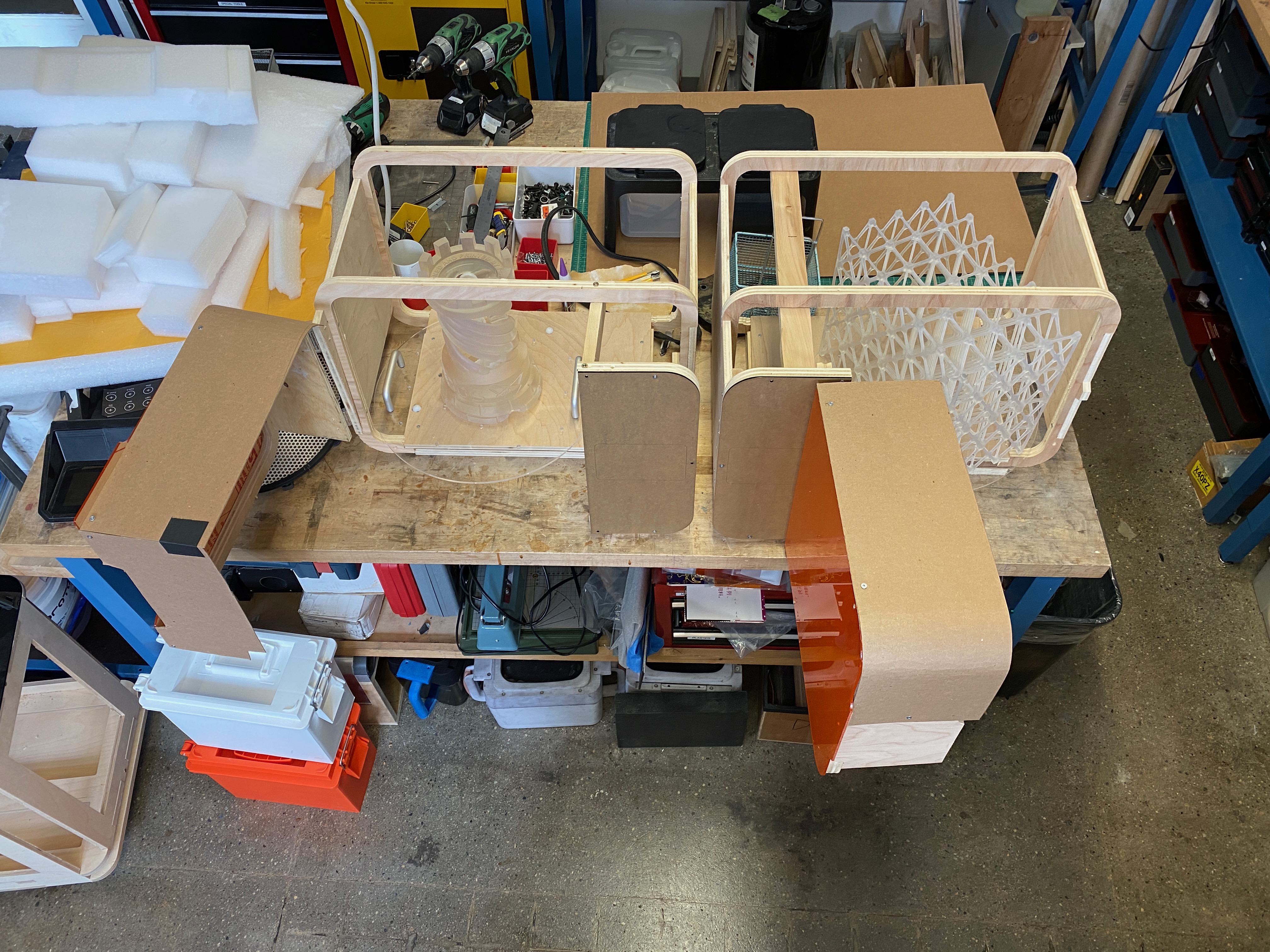

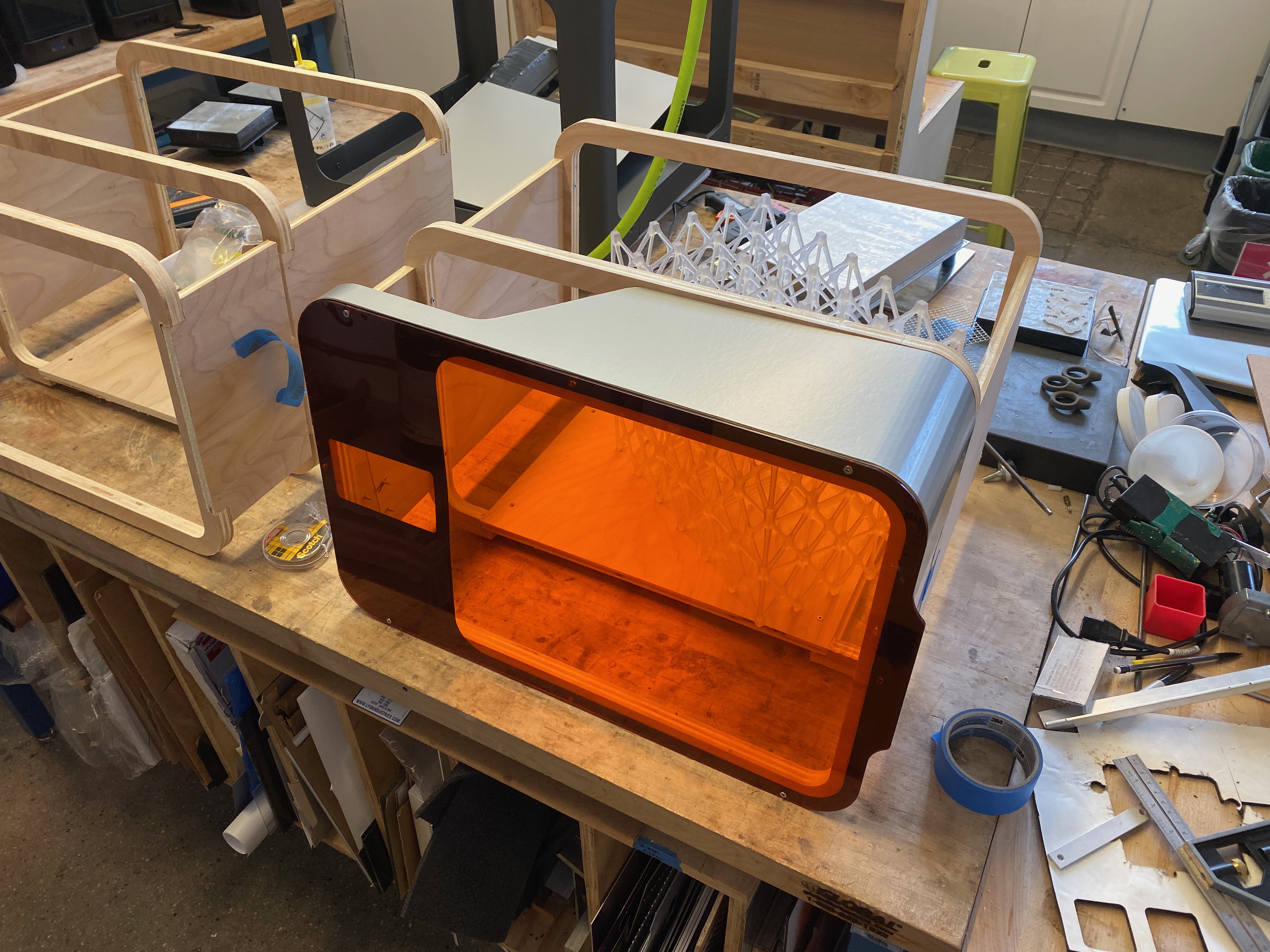

We set out to offer a solution for part washing and part curing to support both large Form 3L SLA prints and high-throughput Form 2/3/3B customers. I led the industrial design of this pair of products from concept to the first production-intent prototype. My work focused on delivering good usability and aesthetic brand fit while operating with minimal engineering resources and an accelerated timeline.

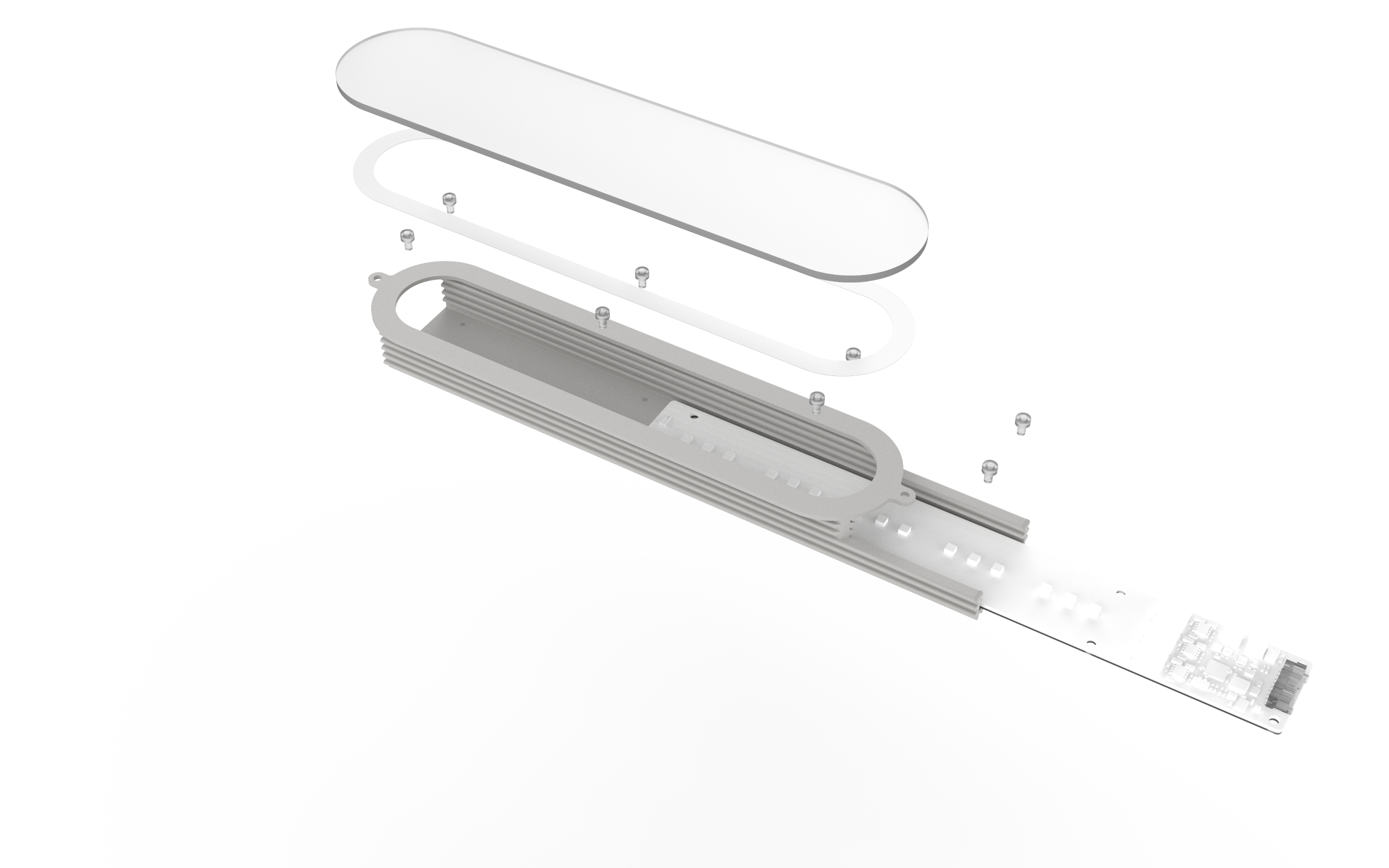

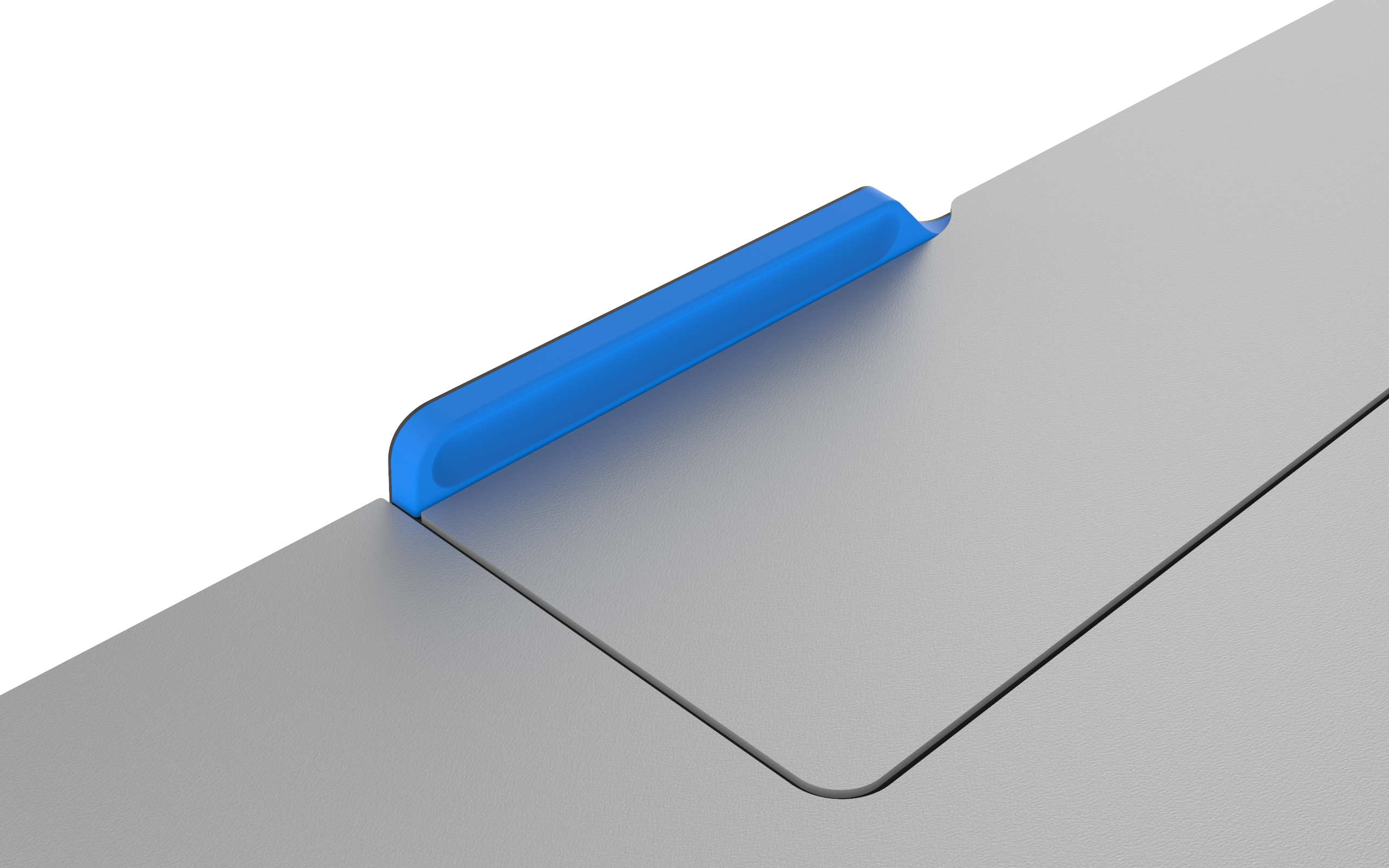

My design contributions were centered on Cure L. The product features a deep door that enables good physical access and visibility to parts from the sides and the top. The door includes a pull tab at the top edge with a contoured silicone handle for improved comfort and grip. A magnetic door latch creates a solid and satisfying feel when opening and closing. The tilt of the front surface provides better touch screen ergonomics and increased access and visibility from the top. The UV light modules are designed to be easily replaced by users for improved product longevity.