I work to create enduring products that serve people.

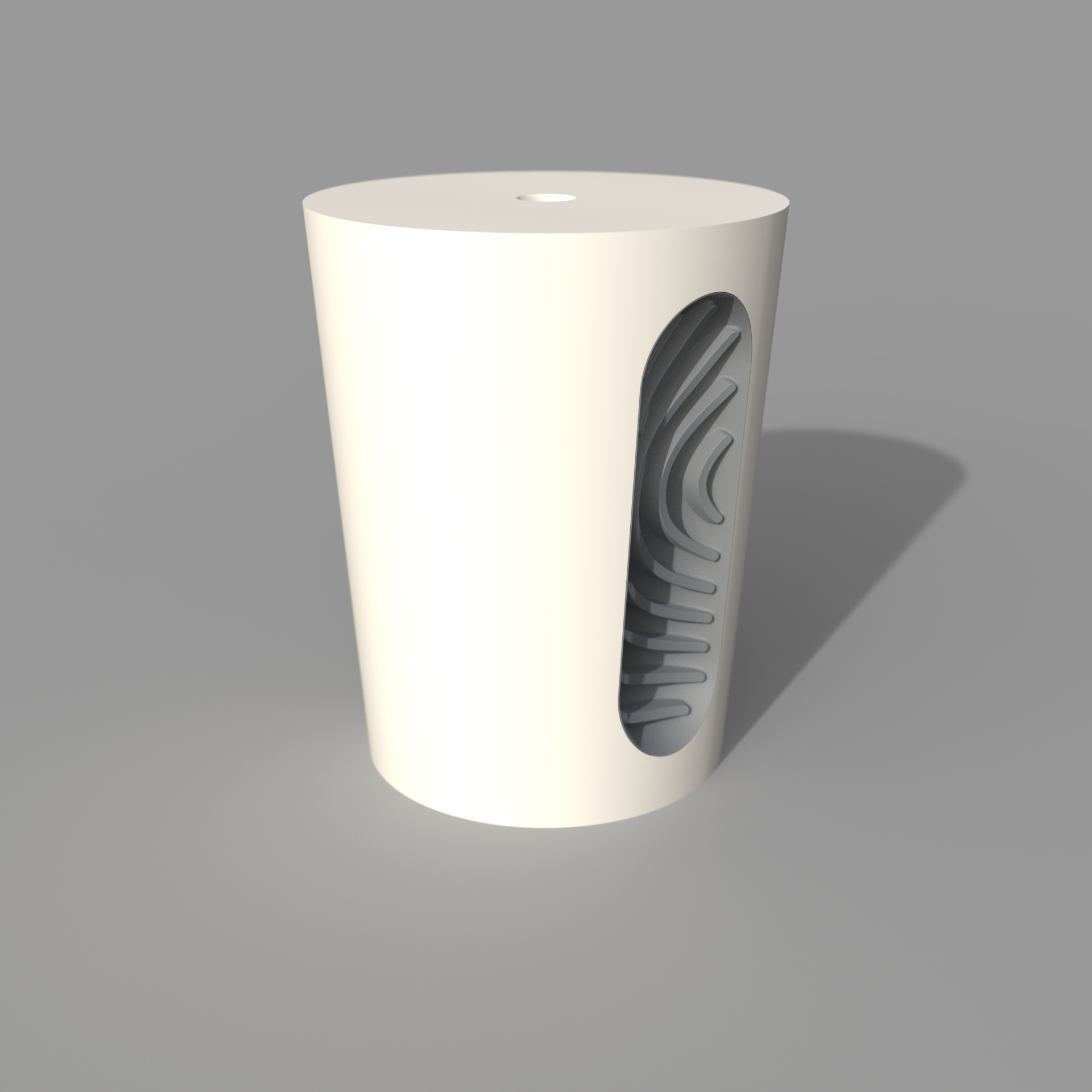

Void cup

2019-2020, personalHandle-free cup for hot beverages

Work

︎ Sketching

︎ 3D modeling

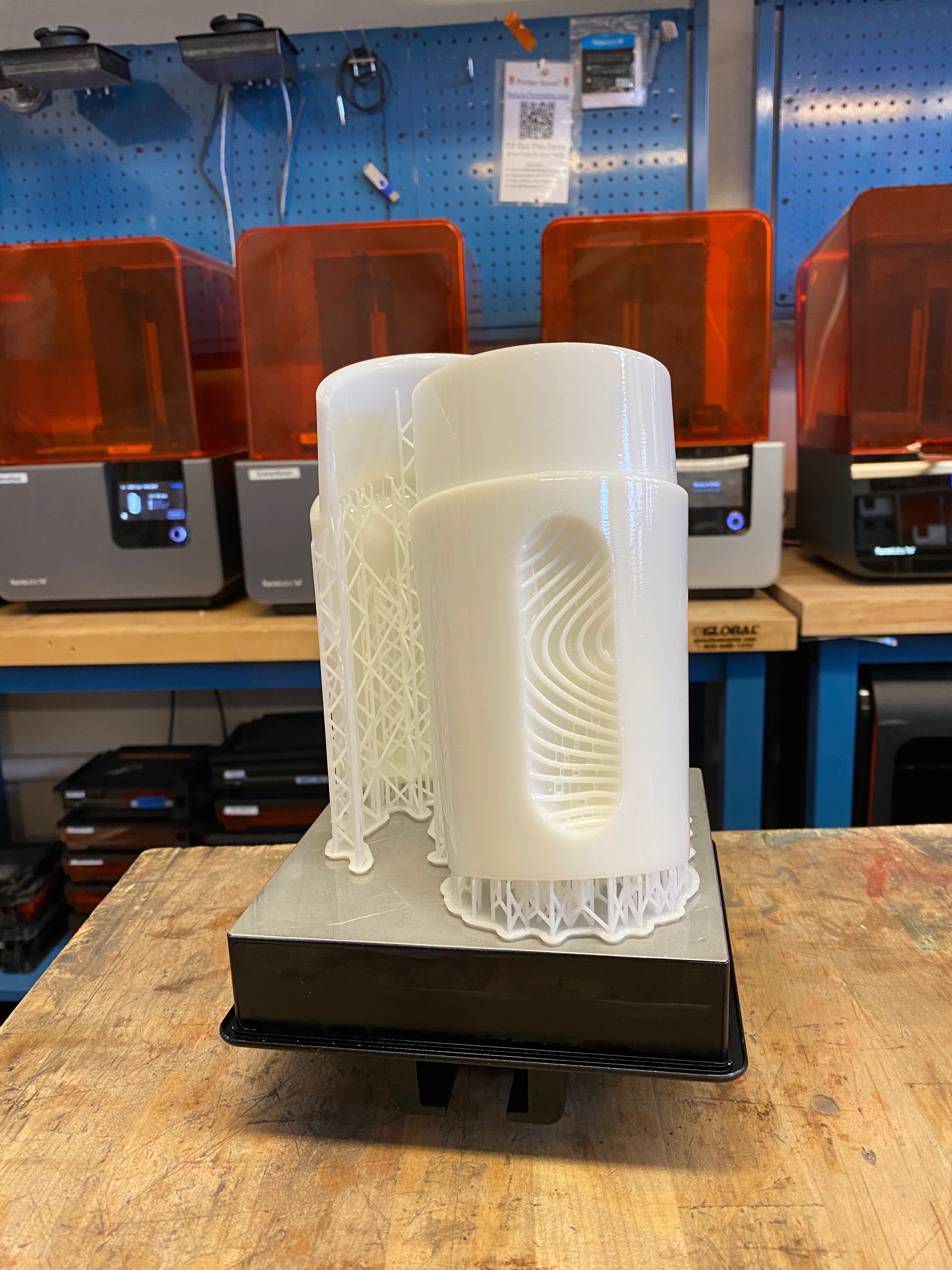

︎ 3D printing, with both soft and hard resins

︎ Porcelain slip casting

︎ Sketching

︎ 3D modeling

︎ 3D printing, with both soft and hard resins

︎ Porcelain slip casting

Goals

︎ Effective insulation

︎ Secure grip

︎ Effective insulation

︎ Secure grip

Despite their ubiquity, I find most mug handles unsatisfying. They often concentrate load on your fingers in uncomfortable ways and cantilever the weight of the liquid, requiring constant torque to keep it upright. I set out to create a cup for hot beverages that would provide sufficient grip and insulation without the need for a handle.

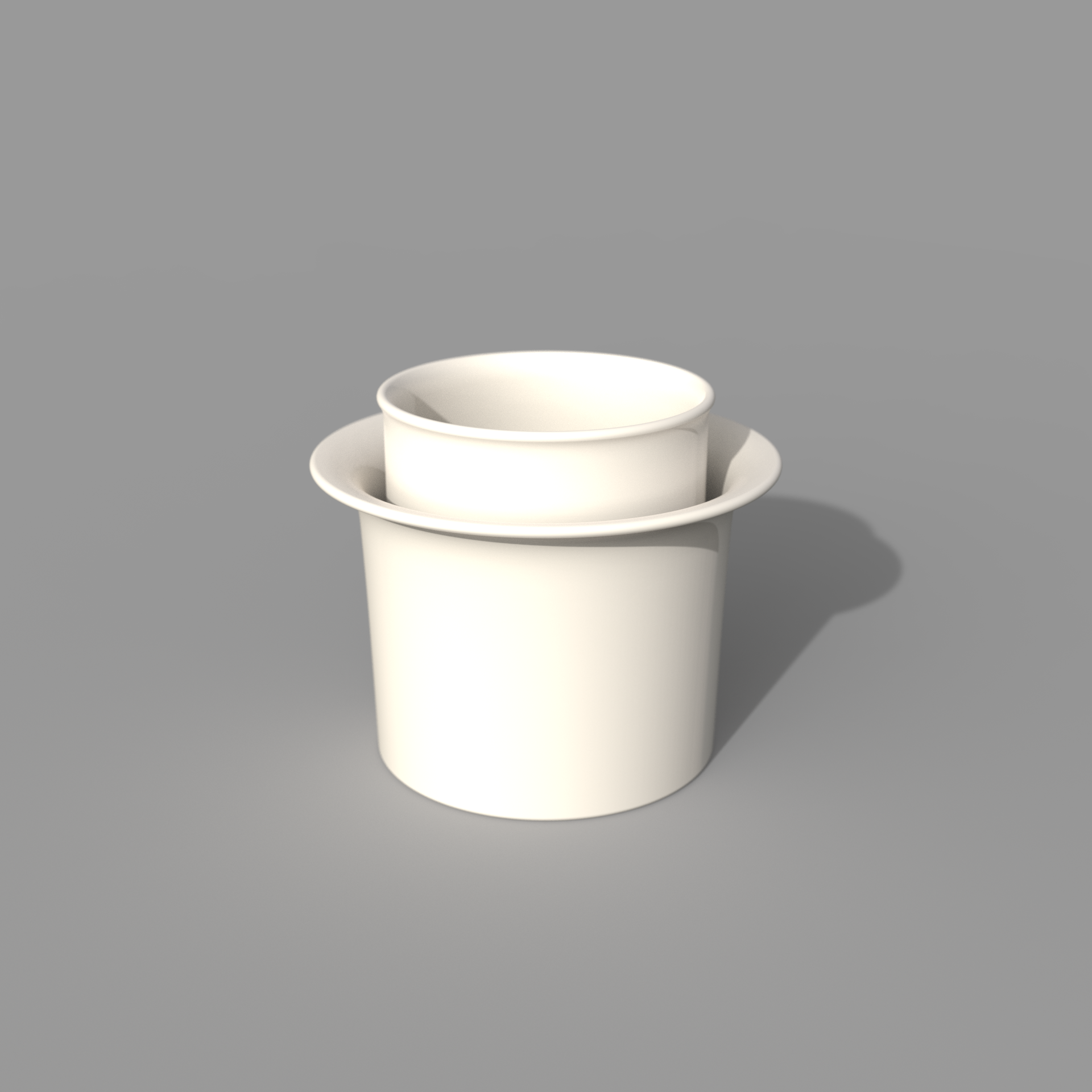

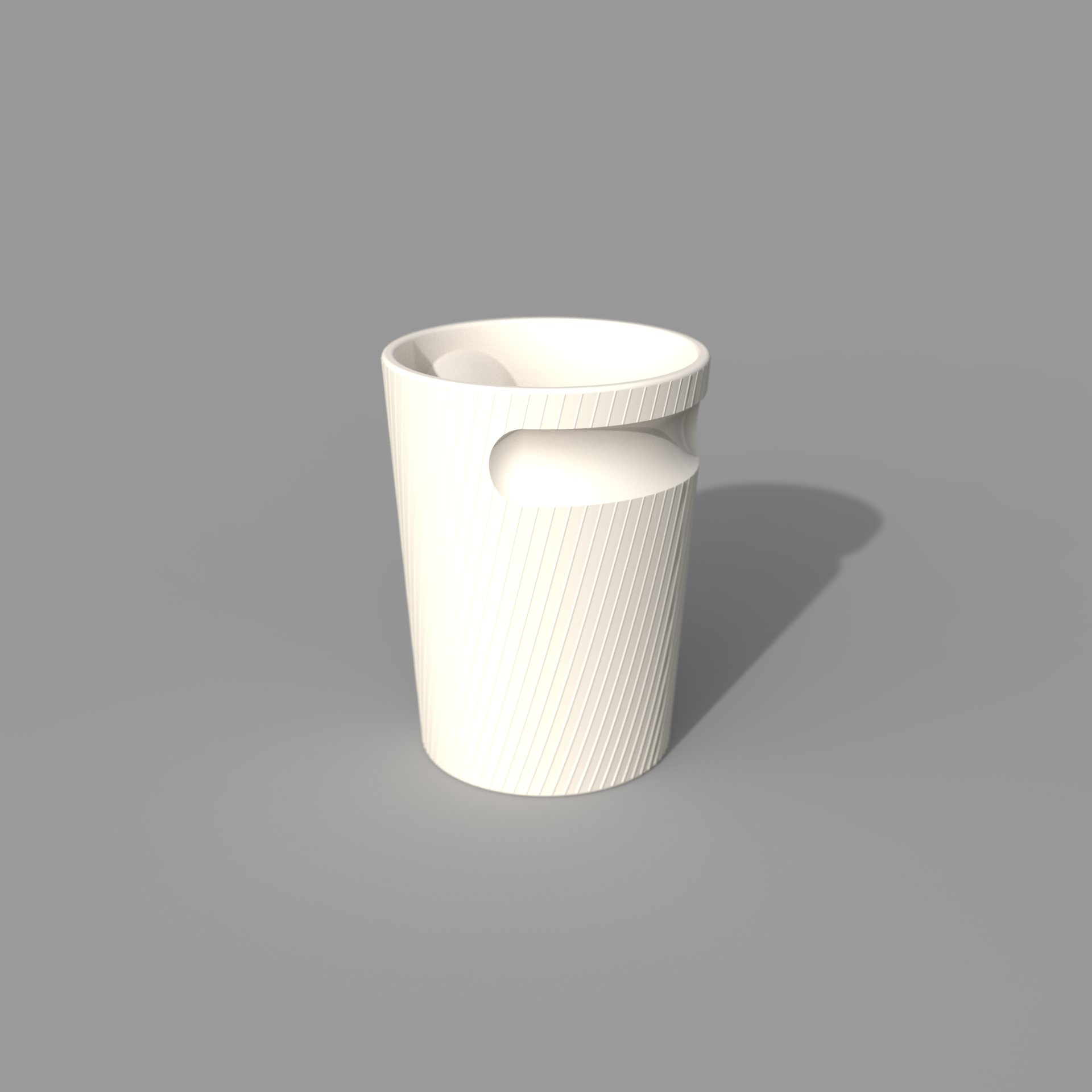

I began by exploring axisymmetric double-wall designs that would both create a thermal barrier and a ridge for grip. Next, I looked at design options that use external ribs to create both of these benefits. While this was a successful direction from a functional perspective, I found the aesthetics overly aggressive and visually noisy.

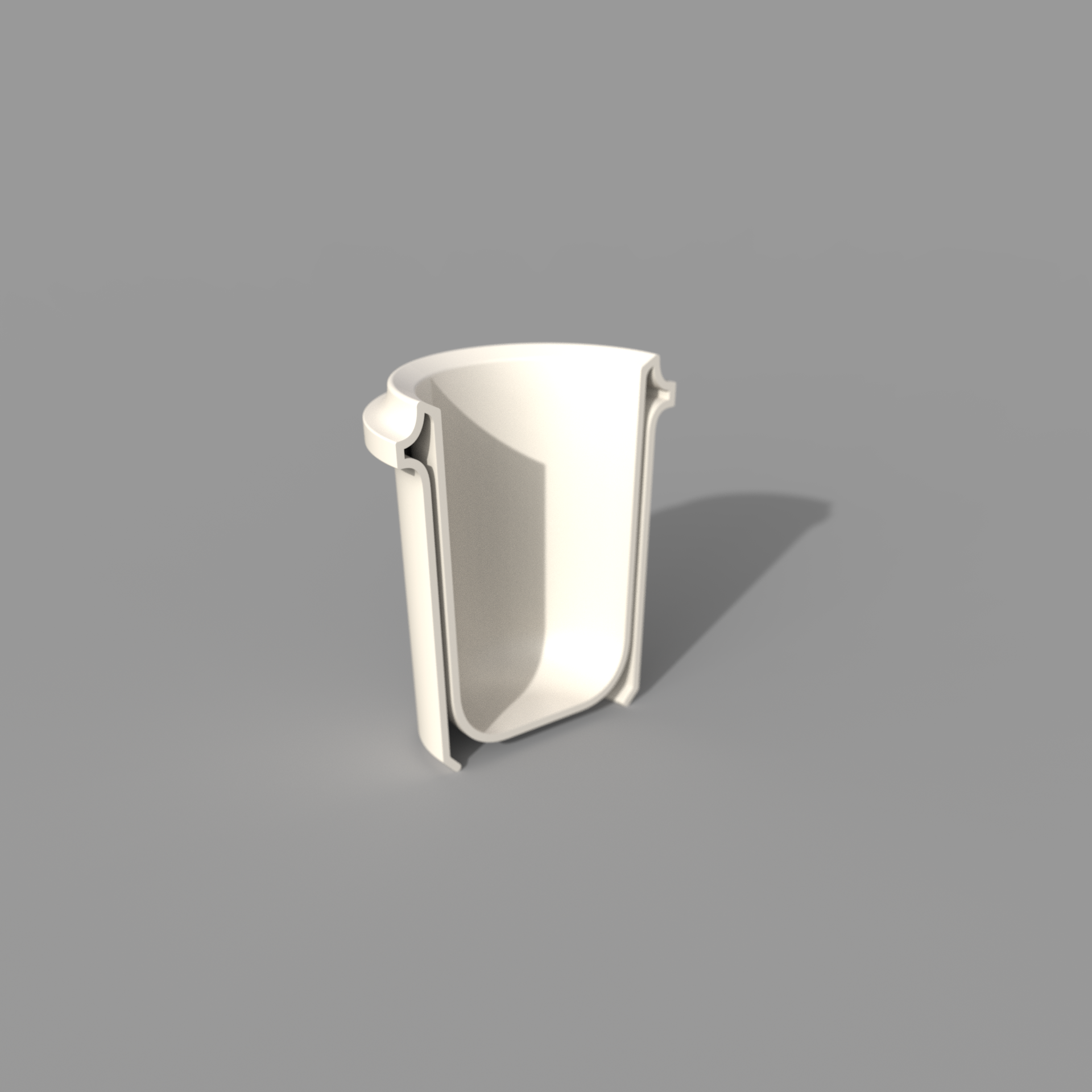

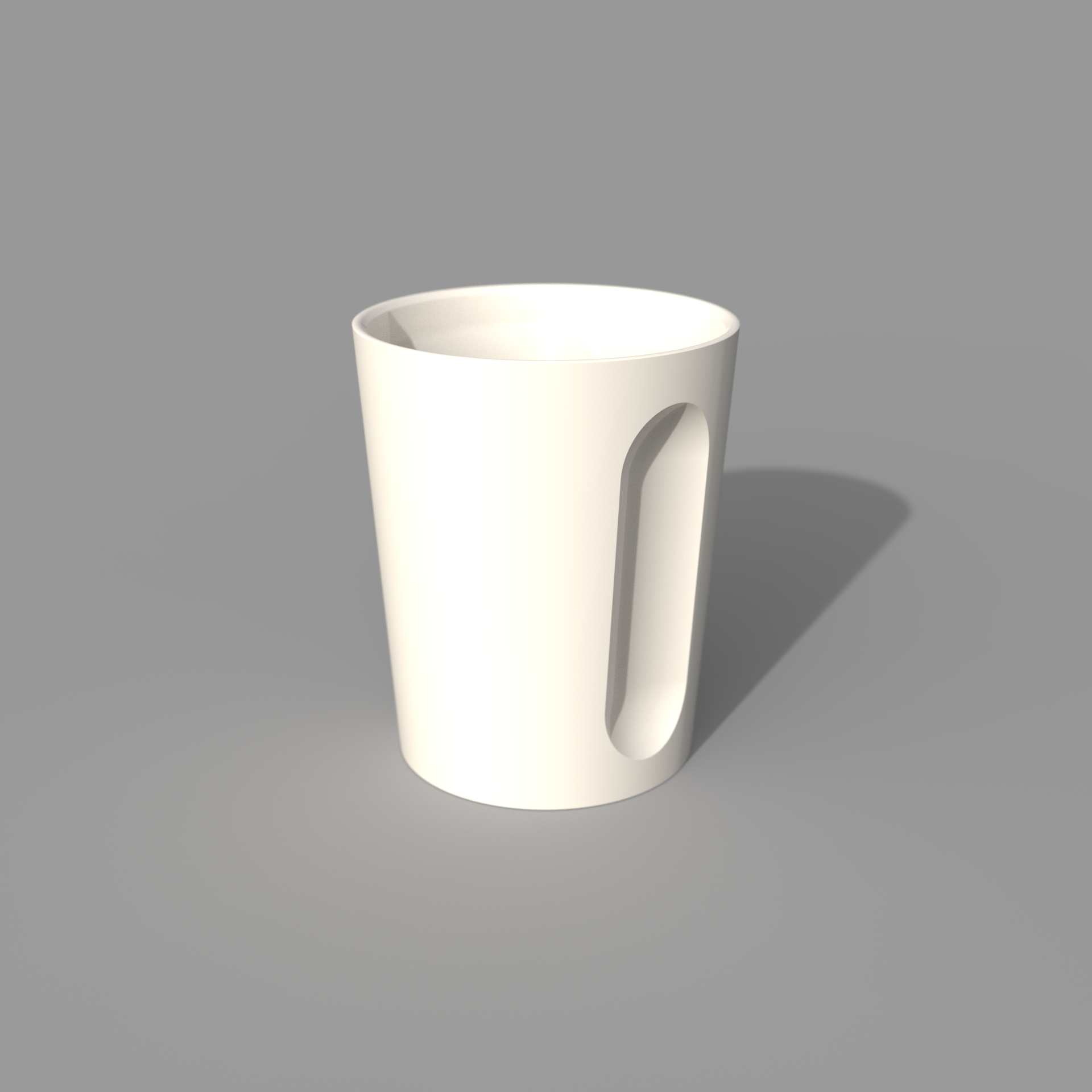

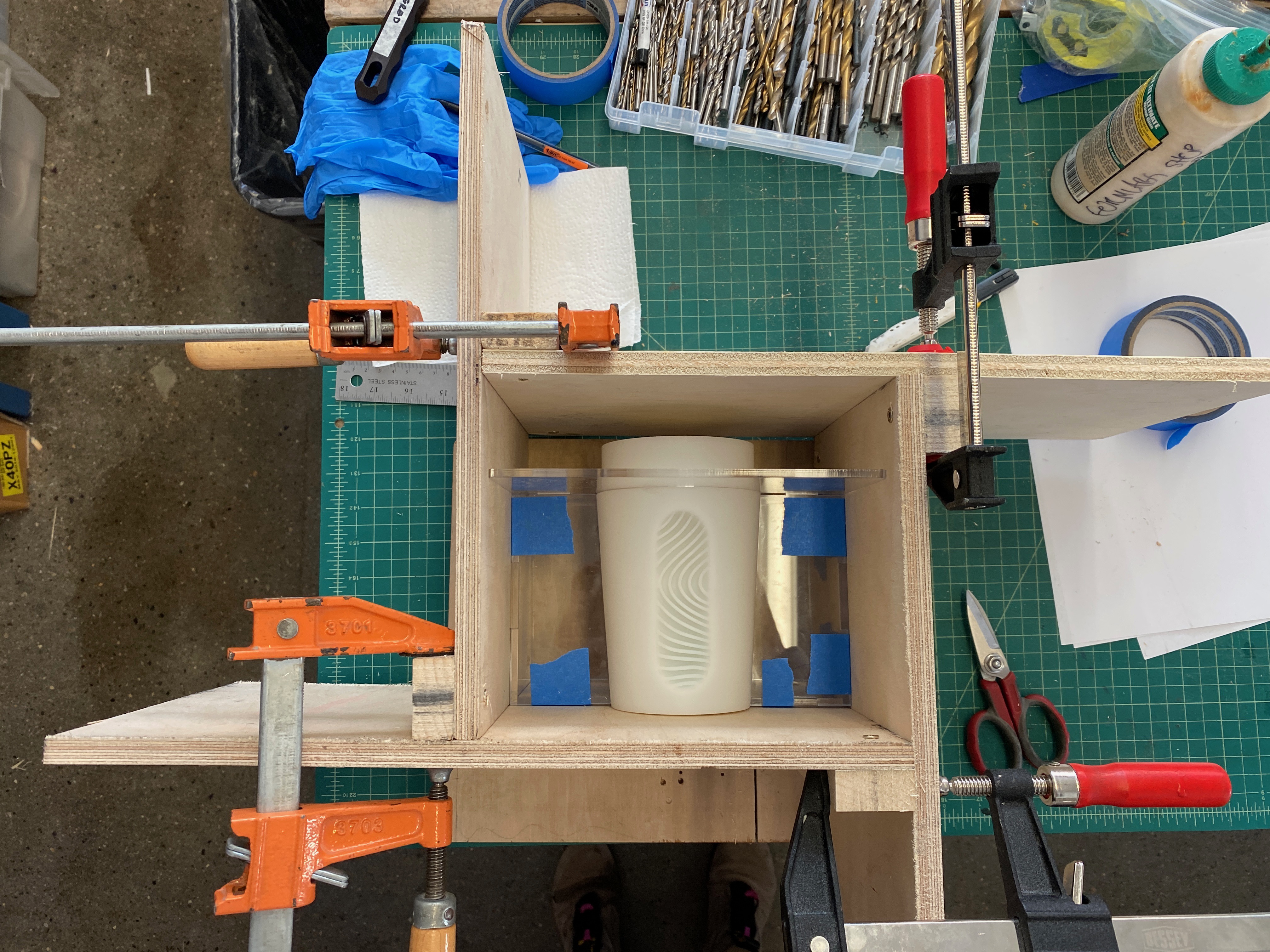

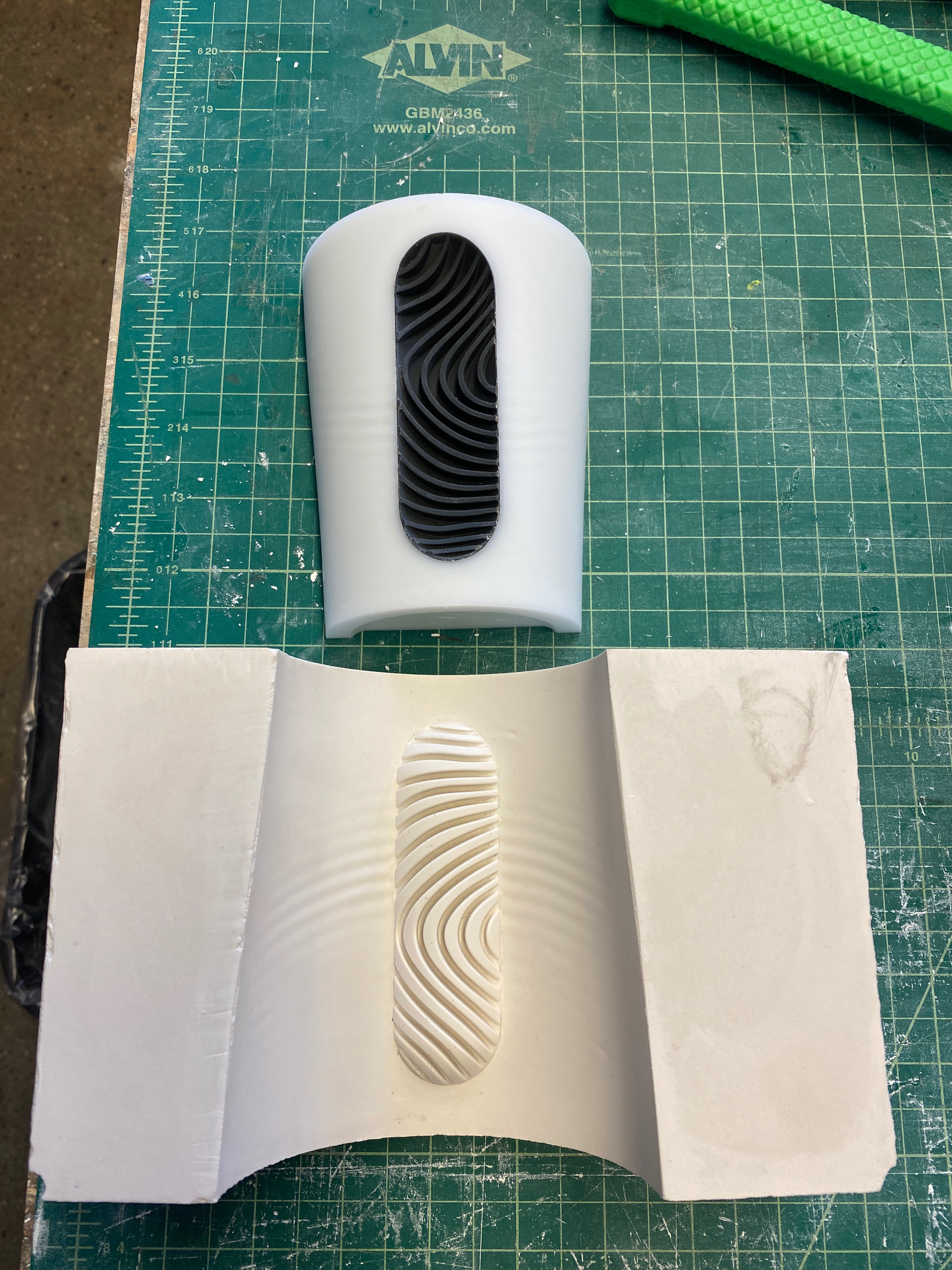

I then looked into designs with simple cuts in the form to serve as grip features and added double walls locally to create an air gap for insulation at the touchpoints. After exploring fabrication options such as multi-part mold slip casting and multi-part ceramic assembly, I decided to find a design that would match the functionality with a more straightforward fabrication process.

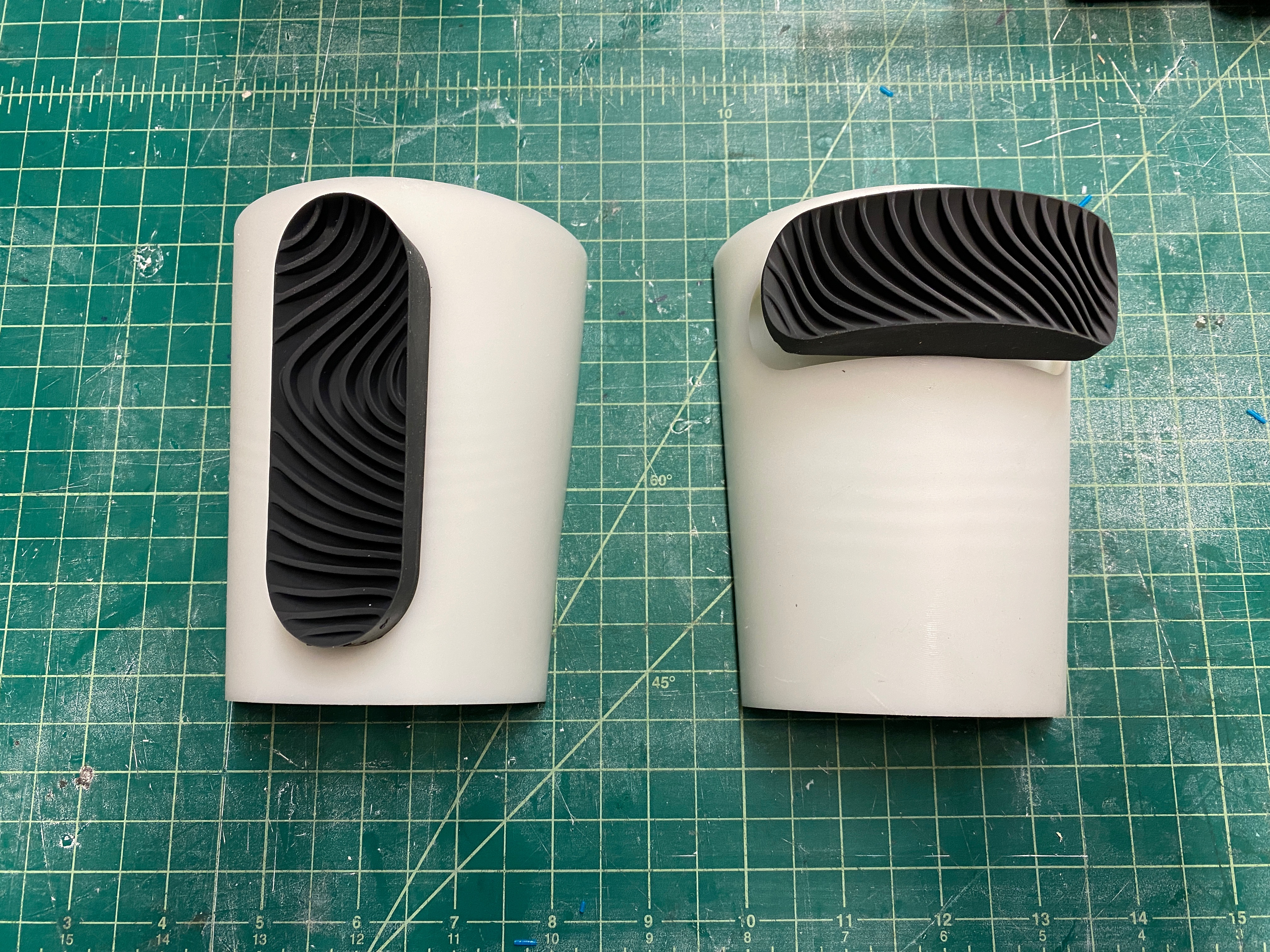

I settled on a direction that uses ribs inside the grip voids to keep fingers separated from the hot interior. With a two-piece slip casting mold, the ribs can be created in draw, allowing the complete part to be created in one molding operation.

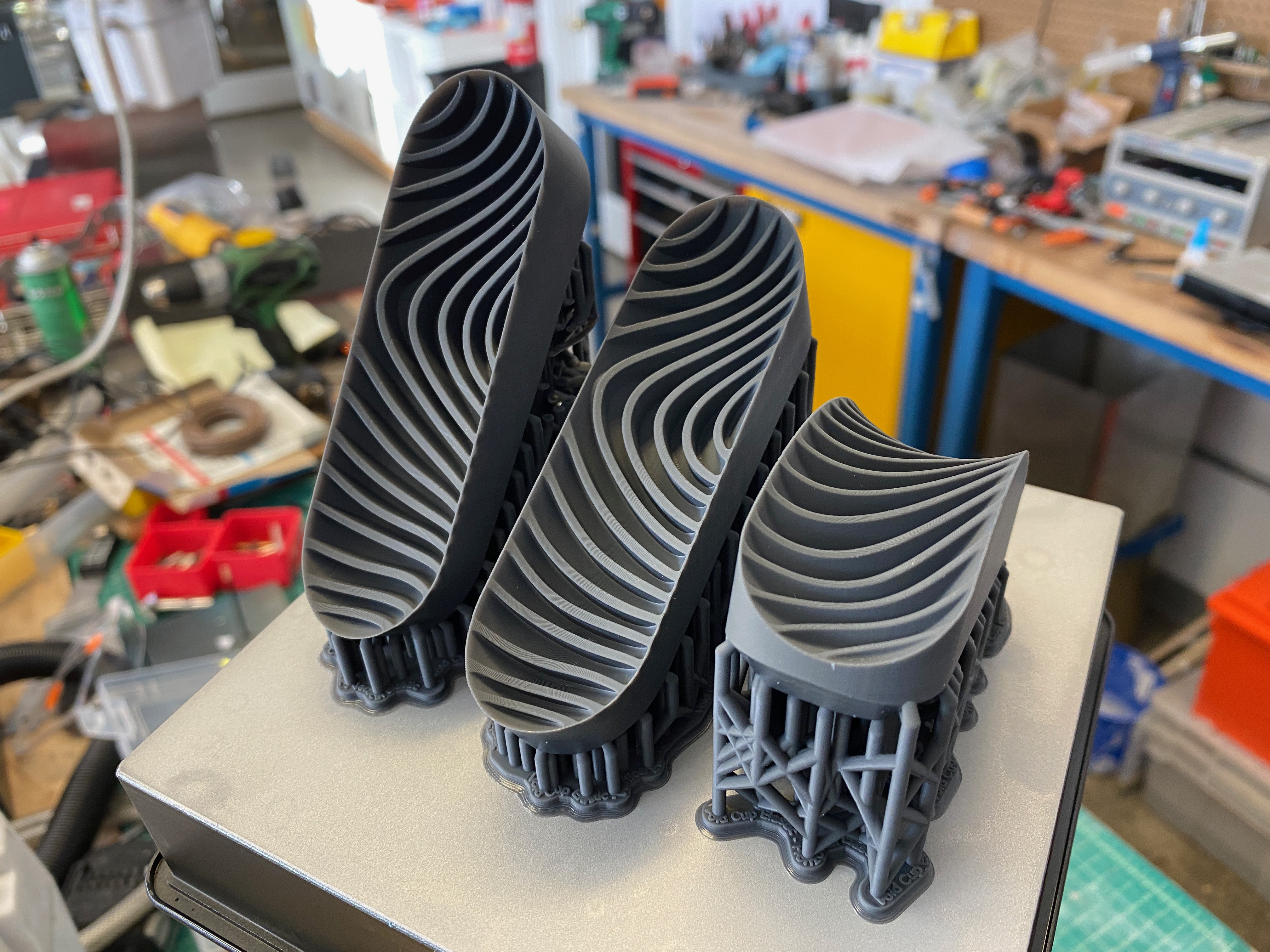

My first molding trials showed me that the rigidity of the cup geometry made it nearly impossible to remove the mold geometry from the positive without breaking fragile plaster features. To address this, I created a cup prototype that uses soft printed inserts (~Shore 80A) in the regions with delicate features. This approach enabled me to successfully remove the plaster from the part without damage.

...this project is still a WIP.