I work to create enduring products that serve people.

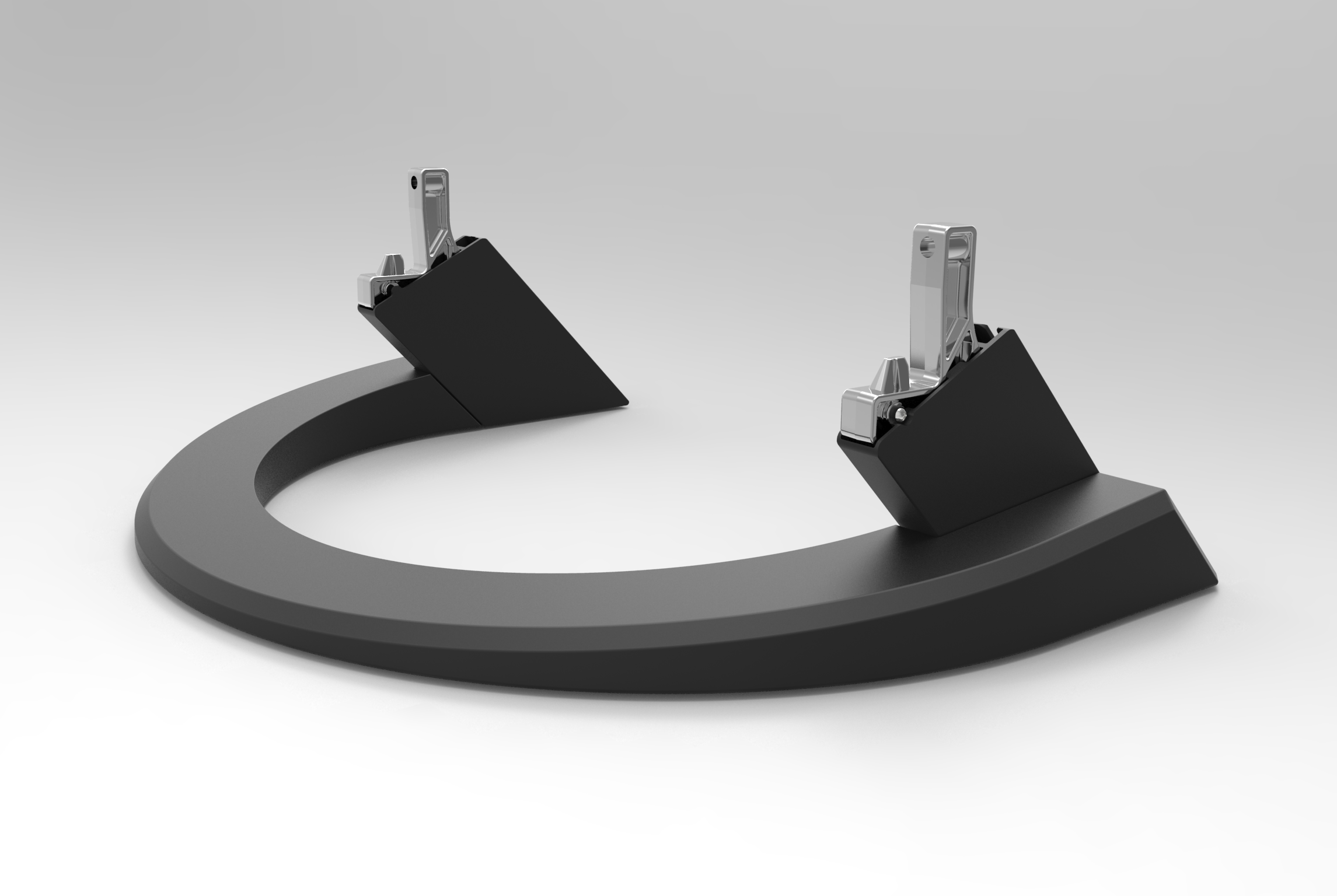

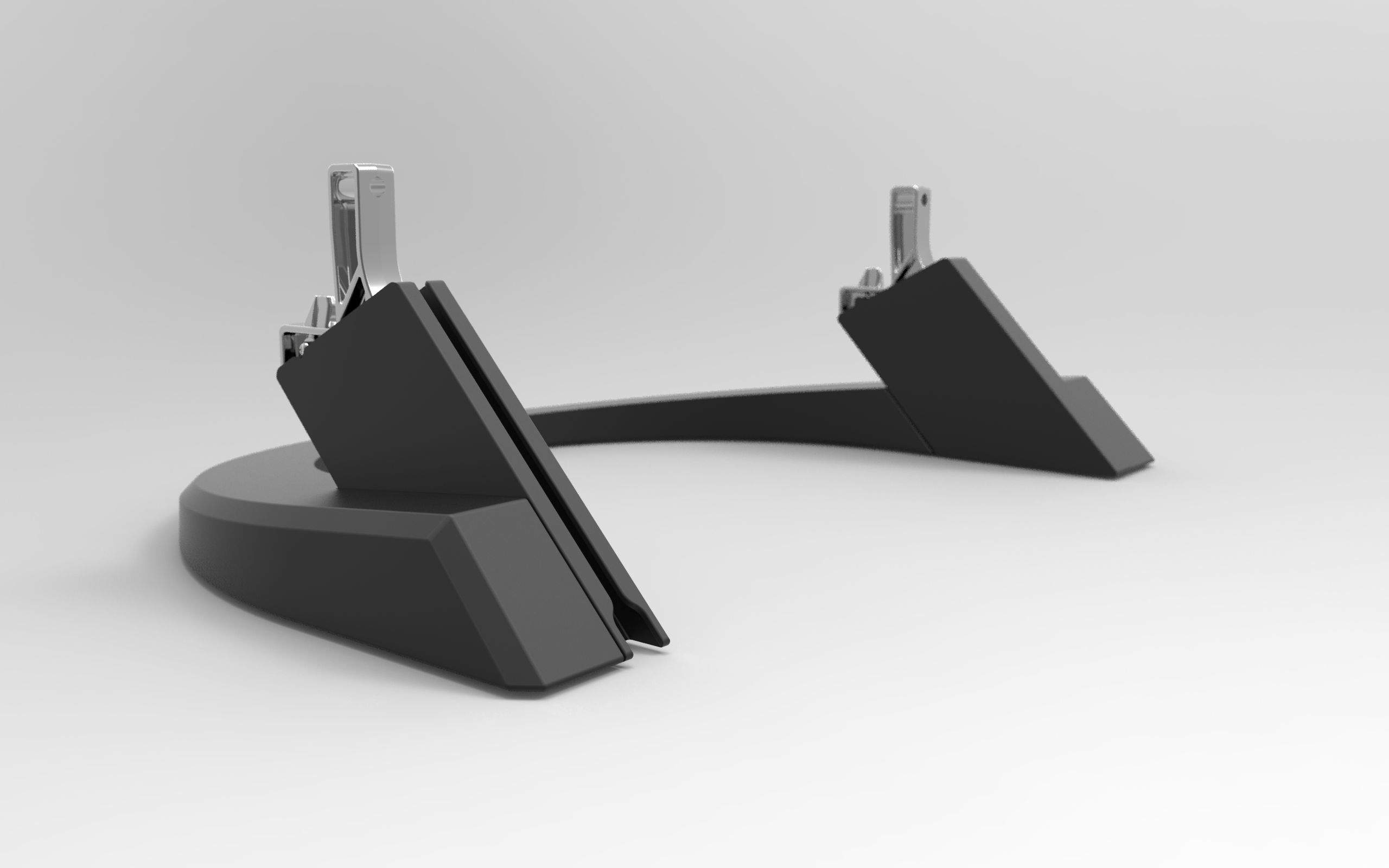

VideoWave TV stand

2010, BoseEnsuring safety for one of the heaviest TVs ever made

Work

︎ 3D modeling

︎ Dynamic analysis of tip/center of gravity

︎ Finite-element analysis to prevent yield during drop

︎ Design of aluminum extrusions and zinc castings

︎ Accelerometer testing of shock levels

︎ 3D modeling

︎ Dynamic analysis of tip/center of gravity

︎ Finite-element analysis to prevent yield during drop

︎ Design of aluminum extrusions and zinc castings

︎ Accelerometer testing of shock levels

Goals

︎ Stability in both tip angle and object impact

︎ Strength to pass drop tests

︎ Easy to disassemble and remove for VESA-mounted applications

︎ Stability in both tip angle and object impact

︎ Strength to pass drop tests

︎ Easy to disassemble and remove for VESA-mounted applications

Roughly every hour, a child in the United States is harmed by a tip-over incident involving furniture or a television. As such, the design of these products requires careful attention to safety.

The VideoWave products were televisions with an integrated home theater audio system packed behind the display. At over 100 lbs., the VideoWave 55” was one of the heaviest TVs ever made and the safety risks were especially heightened. People don’t always follow instructions, so in addition to providing safety straps, our goal was to ensure best-in-class inherent safety against tip.

My task was to design a table stand to achieve good stability when pulled over from the top or impacted by high force. The stand also needed to pass rigorous drop and shipping testing without yielding or fracturing.

The final stability performance adhered closely to predictions and exceeded all competitive TVs surveyed.