I work to create enduring products that serve people.

3D printing accessories

2019, FormlabsAccessories, tools, and packaging

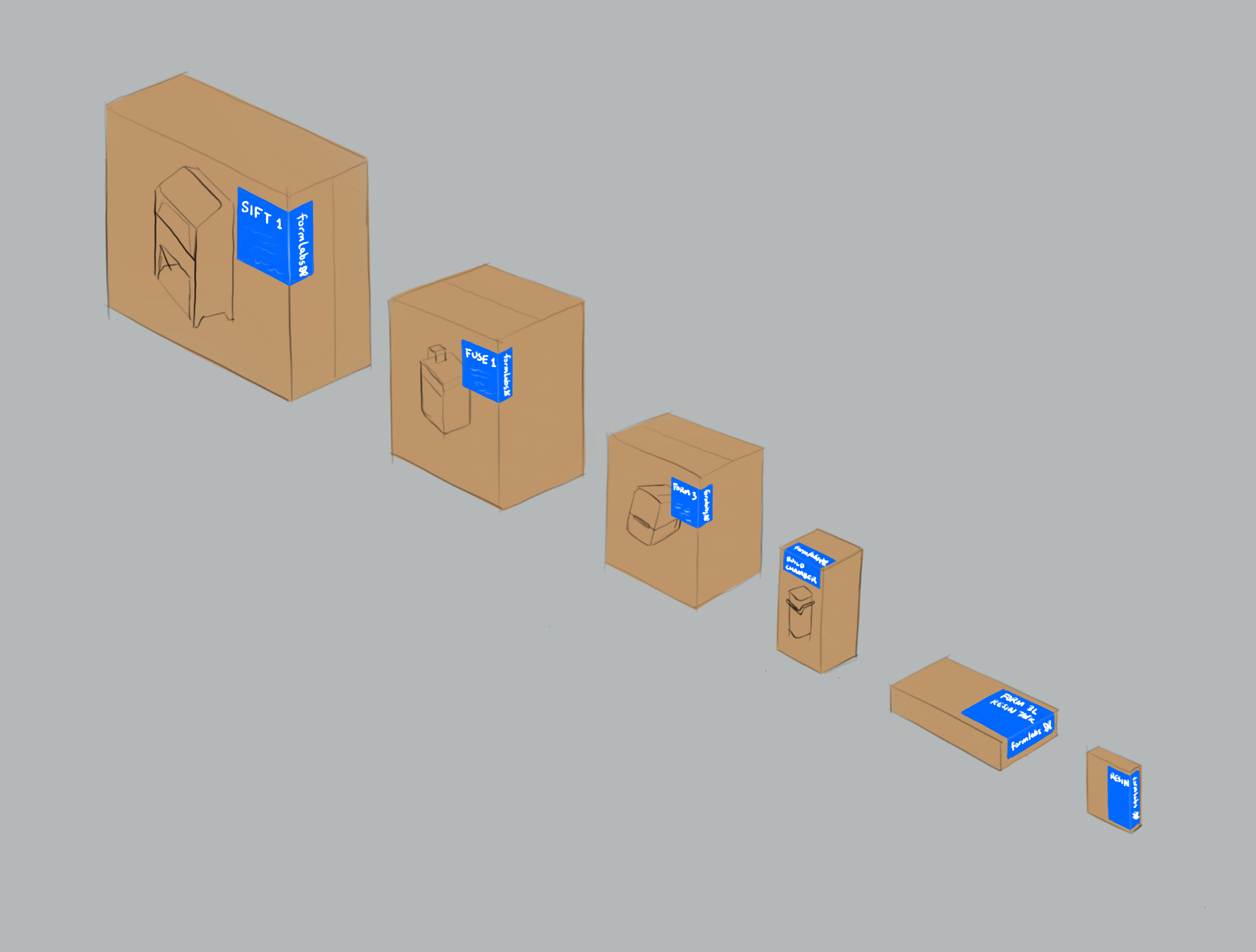

Packaging

I led an effort to develop a new packaging design system for all Formlabs products. My goal was to create a design that is immediately recognizable, easily scalable, and environmentally friendly. Our team achieved this by creating a visually distinctive sticker that contains all the product information. This thick matte tag is printed in Formlabs Blue and comes in three standard sizes for use at different scales. The larger products feature isometric product graphics printed in white. We use the sticker to achieve distinctive brand continuity and boost the quality perception of the package while recycled cardboard is used to reduce the environmental impact.

Below is my first rough sketch and a render of the final design approach.

I led an effort to develop a new packaging design system for all Formlabs products. My goal was to create a design that is immediately recognizable, easily scalable, and environmentally friendly. Our team achieved this by creating a visually distinctive sticker that contains all the product information. This thick matte tag is printed in Formlabs Blue and comes in three standard sizes for use at different scales. The larger products feature isometric product graphics printed in white. We use the sticker to achieve distinctive brand continuity and boost the quality perception of the package while recycled cardboard is used to reduce the environmental impact.

Below is my first rough sketch and a render of the final design approach.

(render by Mathieu Legault)

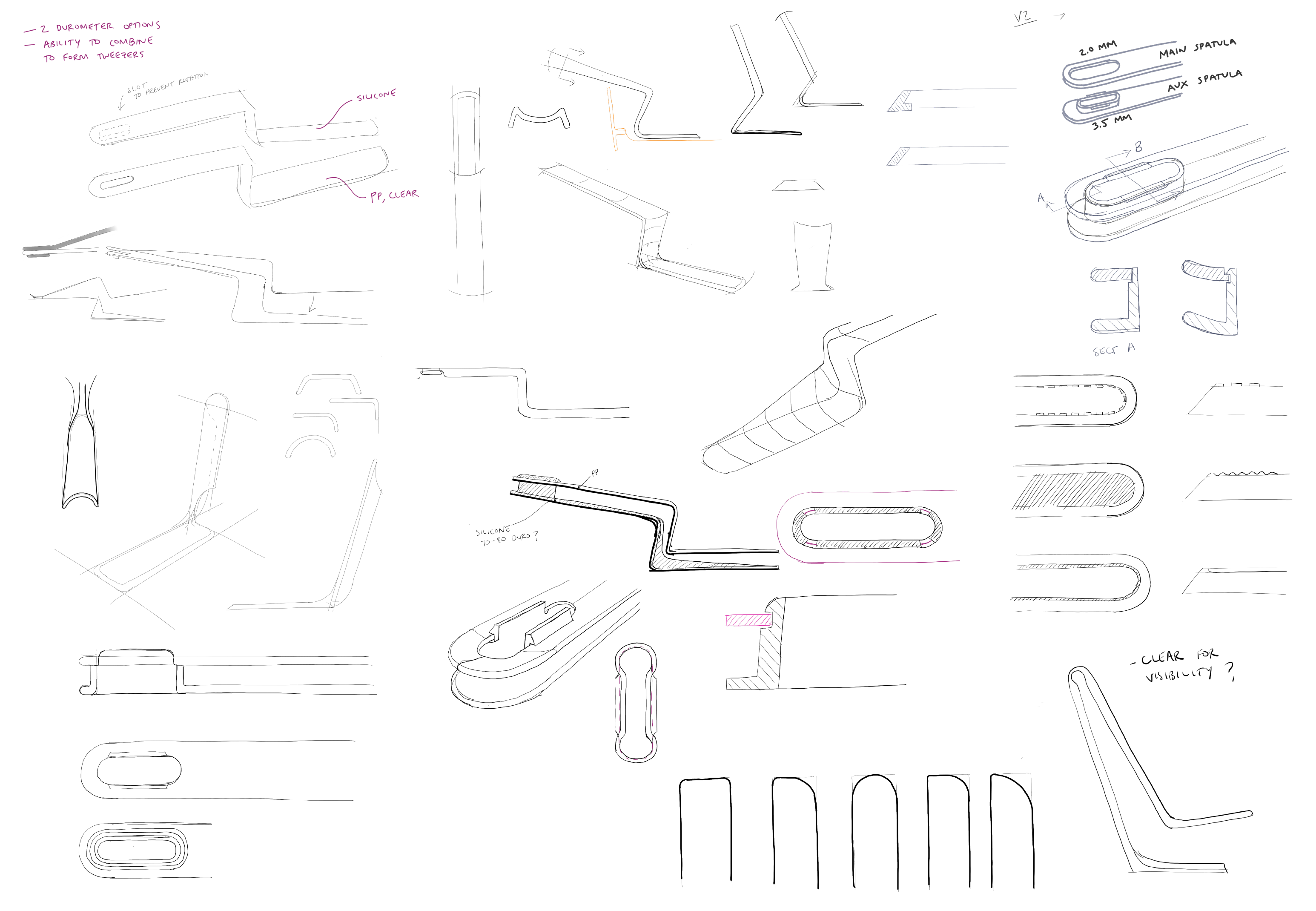

Tank tool

In the rare cases where prints fail, the user is required to remove pieces of cured plastic from the tank before beginning a new print. Sometimes the plastic is firmly adhered to the print surface, while in other cases the parts are floating in the liquid resin. In the past, removal had been performed using tweezers or a metal spatula, depending on the need. However, with the Form 3, the flexible tank film could easily be punctured with metal tools and result in a catastrophic spill.

In the rare cases where prints fail, the user is required to remove pieces of cured plastic from the tank before beginning a new print. Sometimes the plastic is firmly adhered to the print surface, while in other cases the parts are floating in the liquid resin. In the past, removal had been performed using tweezers or a metal spatula, depending on the need. However, with the Form 3, the flexible tank film could easily be punctured with metal tools and result in a catastrophic spill.

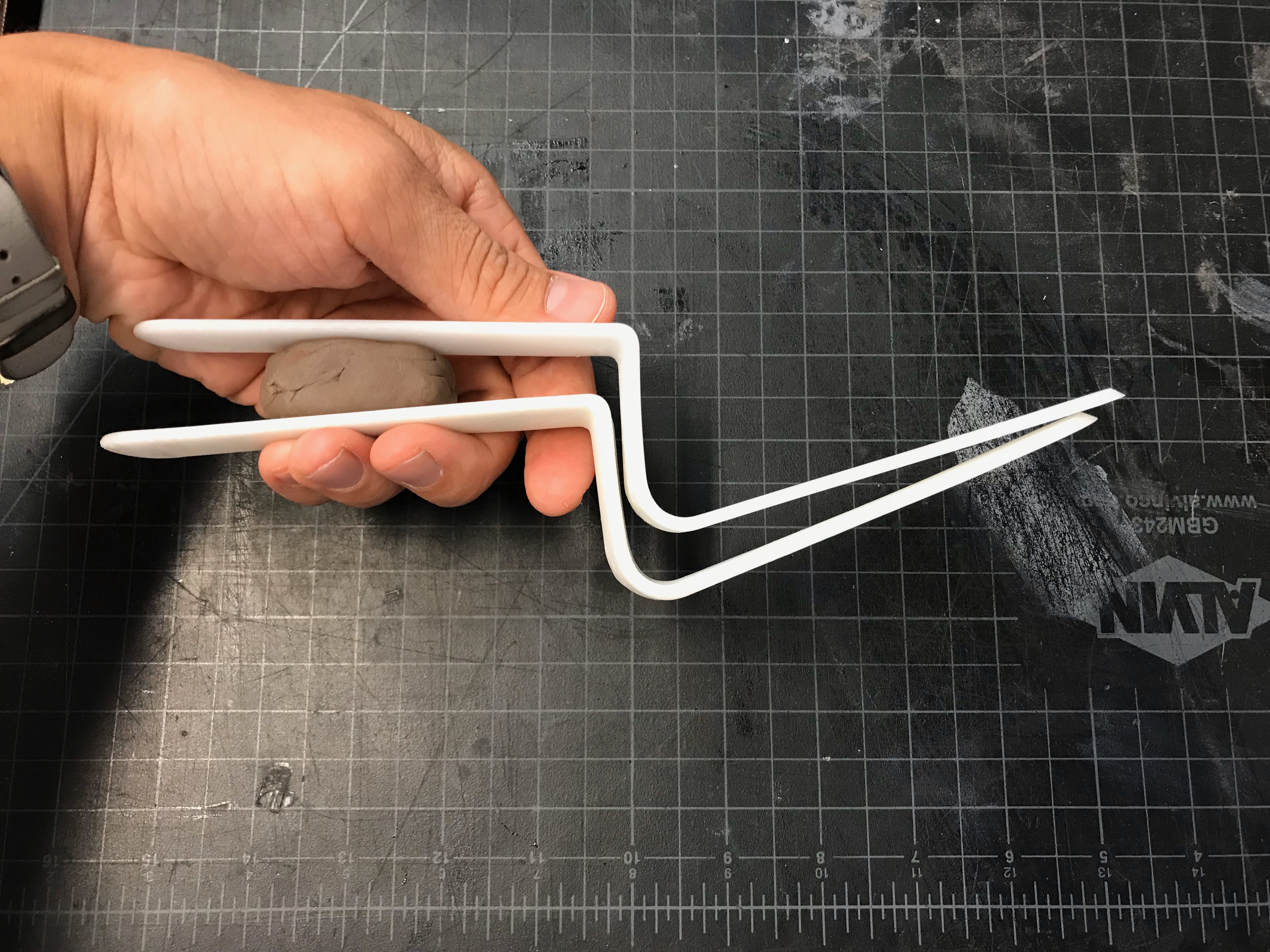

I developed a tool for both the Form 3 and the Form 3L tanks that allows for safe scraping of failed prints and easy removal of floating pieces. The design consists of two separate polypropylene parts that can each be used for delaminating failures from the film surface, and can also snap together to form tongs to squeeze small pieces of failed print and remove them from the tank.

Material labels

Users need to identify tanks by the resin they contain, a problem most users solve by creating labels of their own or writing on the tanks in marker. I developed a concept to ship a pack of material identification stickers with each resin cartridge to provide an easy labeling solution and save users time.

Users need to identify tanks by the resin they contain, a problem most users solve by creating labels of their own or writing on the tanks in marker. I developed a concept to ship a pack of material identification stickers with each resin cartridge to provide an easy labeling solution and save users time.

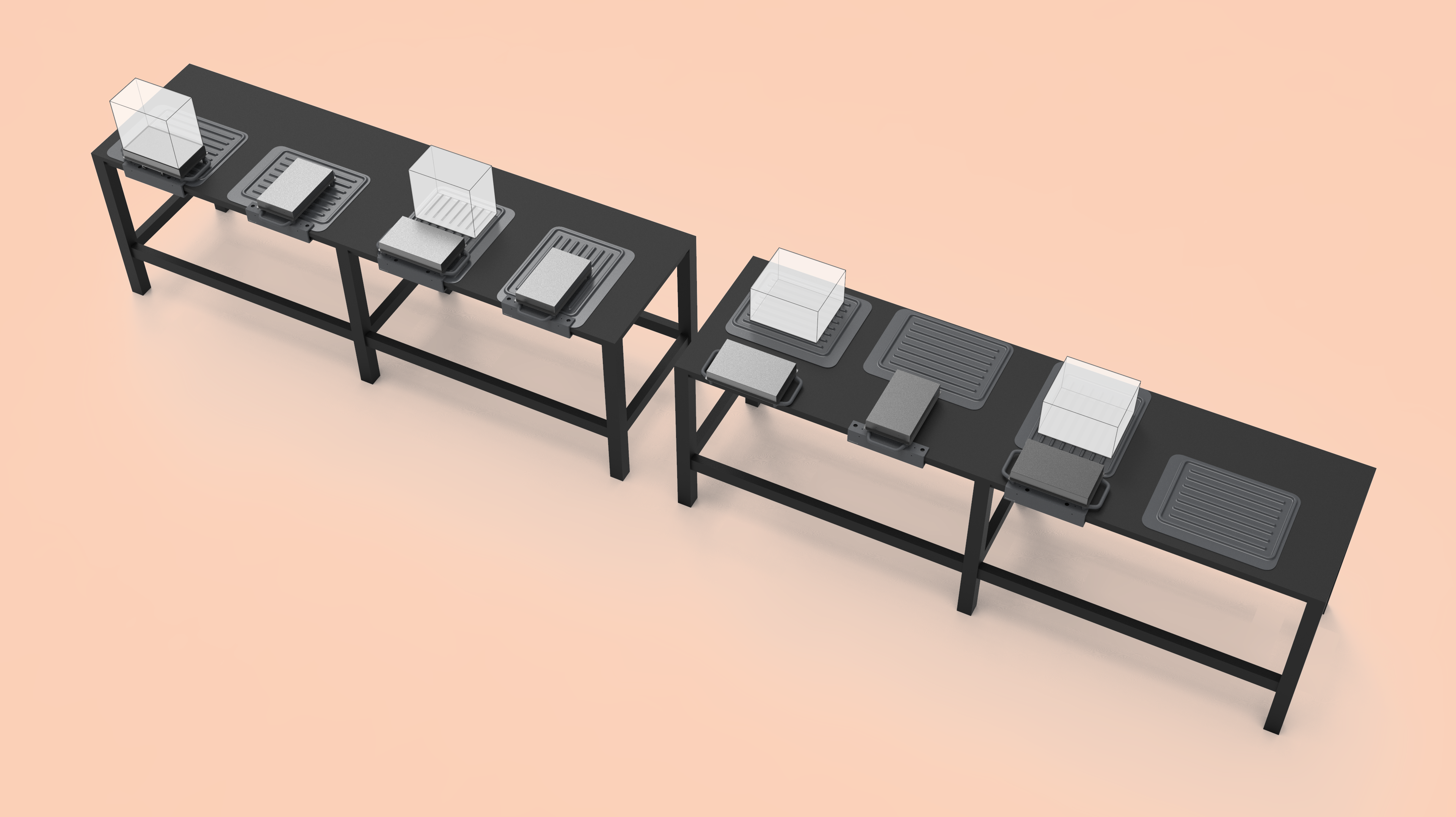

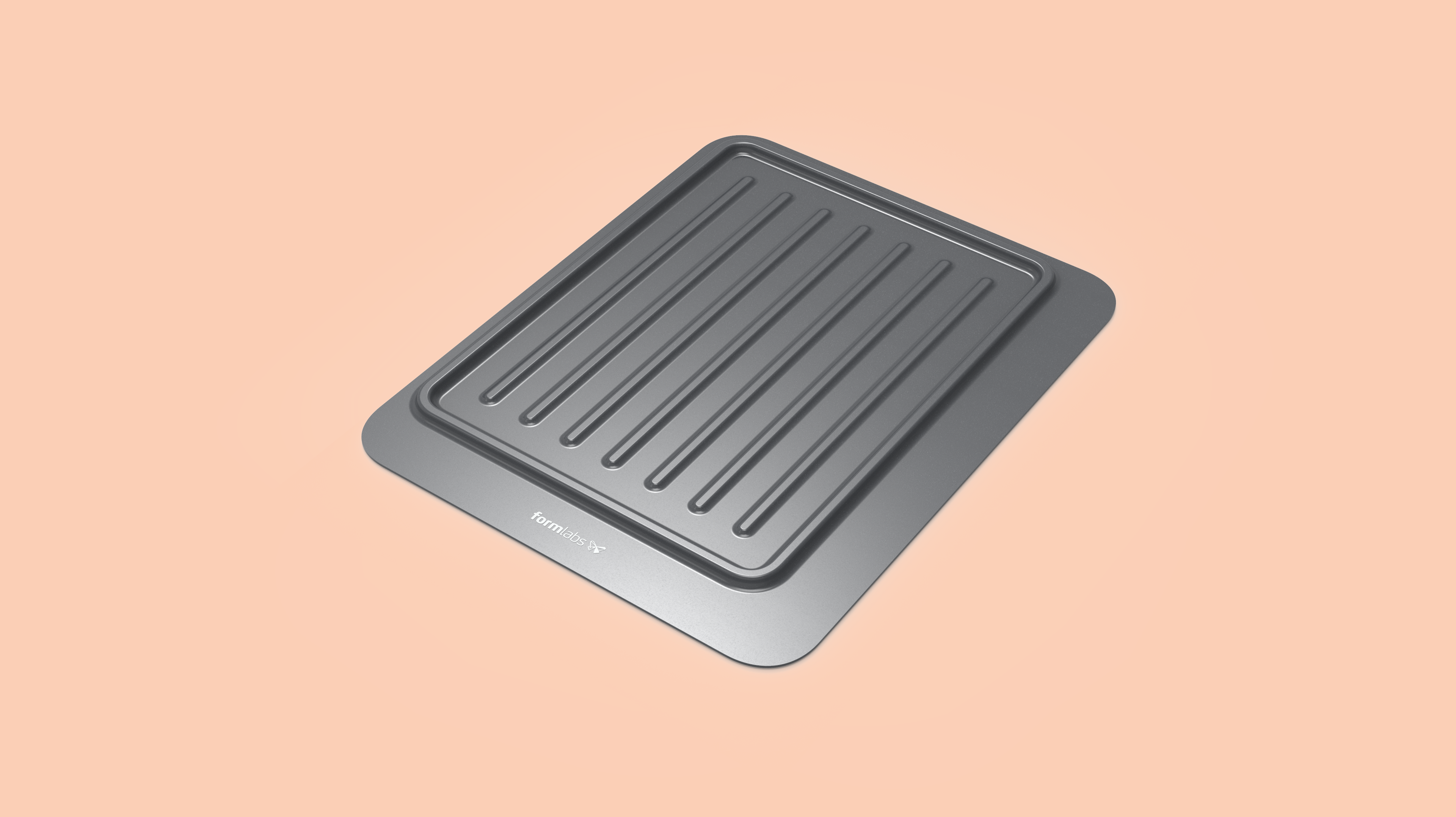

Work surface

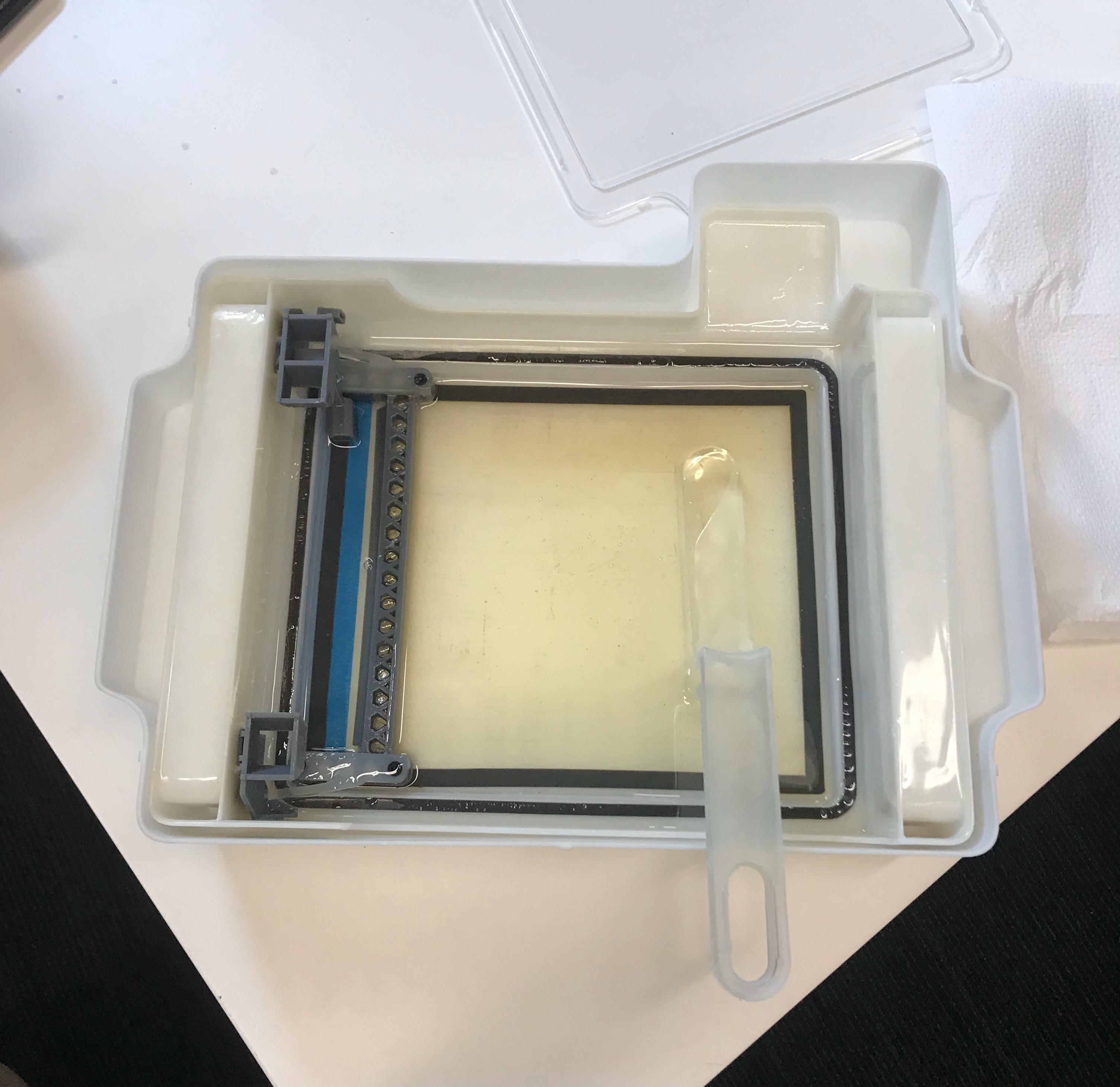

SLA post-processing can be messy, and users often create their own custom stations for doing this work. I developed a design for a work surface that offers a number of improvements to the Formlabs workflow, consisting of a thermoformed polypropylene tray that is chemically compatible with all Formlabs resins. It features a wall around the perimeter to contain resin, IPA, and part debris; there are raised ridges along the center to allow parts to properly air dry without bonding strongly to the surface; and all internal radii are generously sized to allow finger access to wipe the surfaces clean. The product also features a flat area for clamping compatibility with the Form 3L Build Platform jig and rubber strips lining the bottom perimeter to prevent slip.

SLA post-processing can be messy, and users often create their own custom stations for doing this work. I developed a design for a work surface that offers a number of improvements to the Formlabs workflow, consisting of a thermoformed polypropylene tray that is chemically compatible with all Formlabs resins. It features a wall around the perimeter to contain resin, IPA, and part debris; there are raised ridges along the center to allow parts to properly air dry without bonding strongly to the surface; and all internal radii are generously sized to allow finger access to wipe the surfaces clean. The product also features a flat area for clamping compatibility with the Form 3L Build Platform jig and rubber strips lining the bottom perimeter to prevent slip.